GT60 Mining Rock Drill DTH Pipe Water Well MF Extension Speed Drifter Tungsten Carbide Drill Rod

Our advancement depends on the superior gear ,superb talents and consistently strengthened technology forces for Professional Factory for China Te Threaded Ends Longitudinal Submerged Arc Welded Carbon Steel Pipe API5l / ASTM A252 / ASTM A53 /En10219, You would not have any communication problem with us. We sincerely welcome customers all over the world to contact us for enterprise cooperation.

Professional Factory for China Steel Pipes, LSAW, Many items fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don’t ought to waste time shopping around.

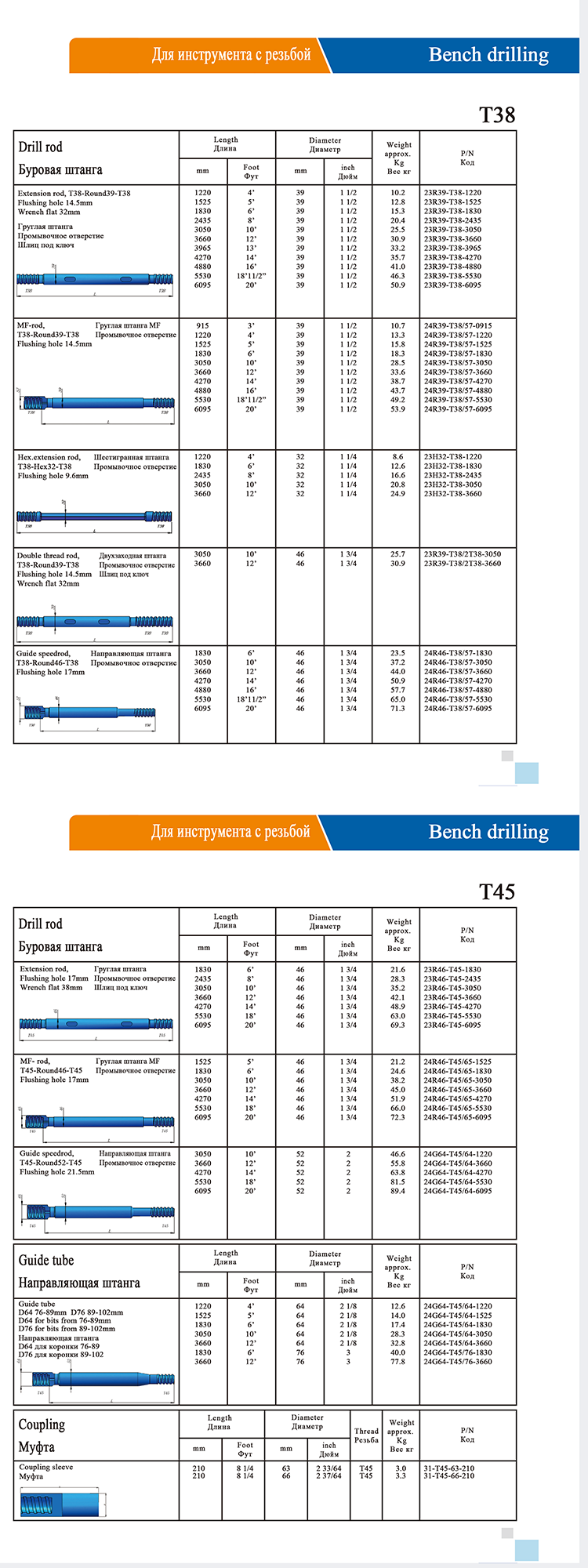

Specification for Drill Rod for hydraulic, top hammer drilling tools

Material:Structural Alloy Steel

Application:Tunnel , Blasting , Mining , Quarrying, Piling, Indutrial water-well, and Infrastructure Construction

Facedrilling and Bolting, Bench Drilling,Production drilling, Long hole drilling

Thread Type:H22,R25,R28,R32,R35,R38,T38,T45,T51,GT60,ST58,ST68

Rod Type:Extension rod,Drifter rod,MF rod,MF Drifter rod, Guide tube, Tapered drill rod, Integral drill steel,Plug hole integral rod

Body Type:Hexagonal type,Round type

Rod Length:260mm~6400mm

CustomDesign:Thread,Diameter,Length, Color can be customized

Connection form: threaded connection type, square connection type, hexagonal connection type

Flat buckle: Φ34.0mm, Φ42.0mm, Φ50.0mm

Cone button: Φ63.5mm, Φ73.0mm, Φ89.0mm

Square connection type: F24, F.26, F30, F32

Hexagonal connection type: B34, B35, B41, B45, B55, B41-B42.5, B48-B49

Application field: Suitable for deep hole drilling construction with geological conditions above medium hard.

Product advantages

The main body of the drill pipe is made of high-quality geological special alloy steel pipe, and the joint of the drill pipe is made of high-quality alloy structural steel. It is manufactured through high-pressure forming, vacuum treatment, friction welding, and overall surface hardening. The thread processing uses advanced automated processing equipment to effectively ensure that each The processing accuracy of each product. It has the characteristics of high bending strength, firm welding and high slag discharge efficiency. Compared with similar products, the fatigue strength and shear strength are greatly improved.

The differentiated design of the spiral blade structure has a wider range of applications for drilling geological conditions. The structural design of the high spiral blade is suitable for deep hole drilling construction with geological conditions above medium and hard, and the structural design of the low spiral blade is suitable for soft and soft geological conditions. Drilling of coal seam and drilling of gas drainage. It has the characteristics of efficient slag discharge, high drilling hole rate and not easy to stick.